Precision Machining Technician

Why choose Precision Machining Technician?

- Machinists create nearly perfect parts for use in aerospace, medical, military, and food industries.

- Machinists also operate and repair custom machining.

- Machining is a great career for those with attention to detail and mechanical aptitude.

- Infusion of new technology into the field has increased the need for skilled machinists today.

- Get the training you need to get started in a machining position. Additional training and experience often lead to advanced positions including quality technician, supervisor, and business owner.

Program Locations

AMETA™ Center

5000 Coye Drive

Stevens Point, WI 54481

Delivery:

In Person

Daytime

Full-Time or Part-Time

Varying Class Schedule

Length of Program: Two Years

Credits: 52-53

Start Dates: Fall or Spring

Start at any time or campus by taking general education courses.

What You'll Learn

The Precision Machining Technician program prepares graduates for machining positions, an in-demand skill set at the heart of industrial production. Additional training and experience often lead to supervisory, quality assurance, and tool maker positions.

In this program you will learn to shape various materials into intricate, precise, usable parts. You’ll also work from blueprints and written specifications to select the proper machinery, materials, and tools, and you’ll gain proficiency with machine tools such as lathes, mills, grinders, computers, and computerized numerical control (CNC) machines.

Outcomes

- Apply basic safety practices in the machine shop.

- Interpret industrial/engineering drawings.

- Apply precision measuring methods to parts inspection.

- Perform basic machine tool equipment setup and operation.

- Perform programming, setup, and operation of CNC machine tools.

- Perform advanced CNC machining operations.

Technical Standards

Students in this program should be able to meet its specific technical standards. These are the essential skills and abilities needed to be successful in the program, with or without reasonable accommodation. It is important to review and understand these standards before applying to the program.

View Technical Standards For This Program

Employability Skills

- Behave Responsibly: Ethical Behavior, Self-Responsibility, Conflict Resolution, Collaboration

- Communicate Effectively: Writing, Technical Documentation, Listening, Speaking, Interpersonal Communication, Reading

- Critical & Creative Thinking: Inquiry, Evidence Collection, Analysis, Reasoning, Reflection (Metacognition)

- Cultural, Social, & Global Awareness: Global Awareness, Social & Cultural Awareness, Social Responsibility

- Use Appropriate Technology: Use of Technology, Confidentiality, Security, Digital Civility

Learn more about employability skills at Mid-State.

Estimated Entire Program Cost

Cost based on the 2025/26 academic year.

- Tuition & Fees: $10,554.60

- Books: $449.69

- Supplies, Uniforms, and/or Exams: $0

- Total Estimated Cost: $11,004.29

Financial Aid Eligibility

This program is eligible for full Financial Aid.

Cost of Attendance

Learn more about Cost of Attendance, an estimated budget that includes categories of expenses a student can expect to incur while attending.

This course has options available to receive credit for prior learning (CPL) or work experience.

| Catalog# | Title | Credits | |

|---|---|---|---|

| 32420331 | Print Reading for Precision Machining | 2 | |

| 32420326 | Introduction to Turning Machines | 2 | |

| 32420373 | CNC Lathes Set Up and Operation | 2 | |

| 32420311 | Safety, Measurement and Layout | 1 | |

| 32420329 | Intermediate Turning Applications | 5 | |

| 31804305 | Applied Mathematics | 2 | |

| -or- | 10804107 | College Mathematics | 3 |

| Term Total | 14-15 Credits | ||

| Catalog# | Title | Credits | |

|---|---|---|---|

| 32420310 | Introduction to Solid Modeling | 2 | |

| 32420337 | Introduction to Milling Machines | 2 | |

| 32420374 | CNC Mills Set Up and Operation | 2 | |

| 32420340 | Intermediate Milling Applications | 5 | |

| 31801368 | Workplace Communication | 1 | |

| Term Total | 12 Credits | ||

| Catalog# | Title | Credits | |

|---|---|---|---|

| 32420332 | Materials and Machinability | 2 | |

| 32623301 | Manufacturing Principles | 1 | |

| 32420325 | Inspection with Geometric Dimensioning | 2 | |

| 32420362 | CNC Lathes/Manual Programming | 2 | |

| 32444377 | CNC Lathes Computer Aided Programming | 2 | |

| 32420330 | Advanced Turning Applications | 3 | |

| Term Total | 12 Credits | ||

| Catalog# | Title | Credits | |

|---|---|---|---|

| 32420380 | Multi-Axis Machining Processes | 3 | |

| 32420364 | CNC Mills/Manual Programming | 2 | |

| 32444378 | CNC Mills Computer Aided Programming | 3 | |

| 32444379 | Advanced CNC Milling Operations | 3 | |

| 32420341 | Advanced Milling Applications | 3 | |

| Term Total | 14 Credits | ||

| Program Total | 52-53 Credits |

Instructors

MIKE BERRY, BS

Mike earned his bachelor’s degree from UW–Stout and is a certified journey worker machinist. He has worked for local manufacturers and maintains constant contact with industry leaders, giving him a real-life understanding of what they need from their employees.

“Teaching at Mid-State allows me to give back to a trade I have found so much satisfaction in being a part of.”

JOE BYCZYNSKI

Joe earned his Journeyman Machinist license from Northcentral Technical College and his technical diploma in machine tool operations from Mid-State Technical College. His extensive experience includes working in the metal manufacturing sector since 1987, where his roles included everything from project manager to shop owner.

“Being a Precision Machining Technician instructor is a great way for me to utilize my unique experiences and pass my knowledge on to the future generation of machinists.”

KERRY DUCKART, BS

Kerry earned his Machine Tool Technician technical diploma from Mid-State Technical College in 2002. He also holds a bachelor’s degree from UW-Stout in business management with emphasis in operations management. His 17 years of industry experience include five years in a local machine job and 12 years working for an OEM company where he advanced to machine shop manager.

“I love having the opportunity to teach skills that have allowed me a successful career as a machinist.”

Careers

- Advanced Machine Operator

- CNC Machine Operator

- Job Shop Machinist

- Apprenticeship

- CNC Operator

- CNC Programmer

- Machine Operator

- Machinist

- Maintenance Machinist

- Tool Room Machinist

- Quality Control Technician

- Metrology Technician

Video

Fast-Track

High school students are eligible to enroll in this program and all courses required. Learn more about Mid-State Fast-Track.

Take the Next Step

“I value my experience at Mid-State tremendously. Even with a disability my education gave me the opportunity to join the workforce before I even graduated. Education equals opportunity.”

JAKE ANDERSON

GRADUATE

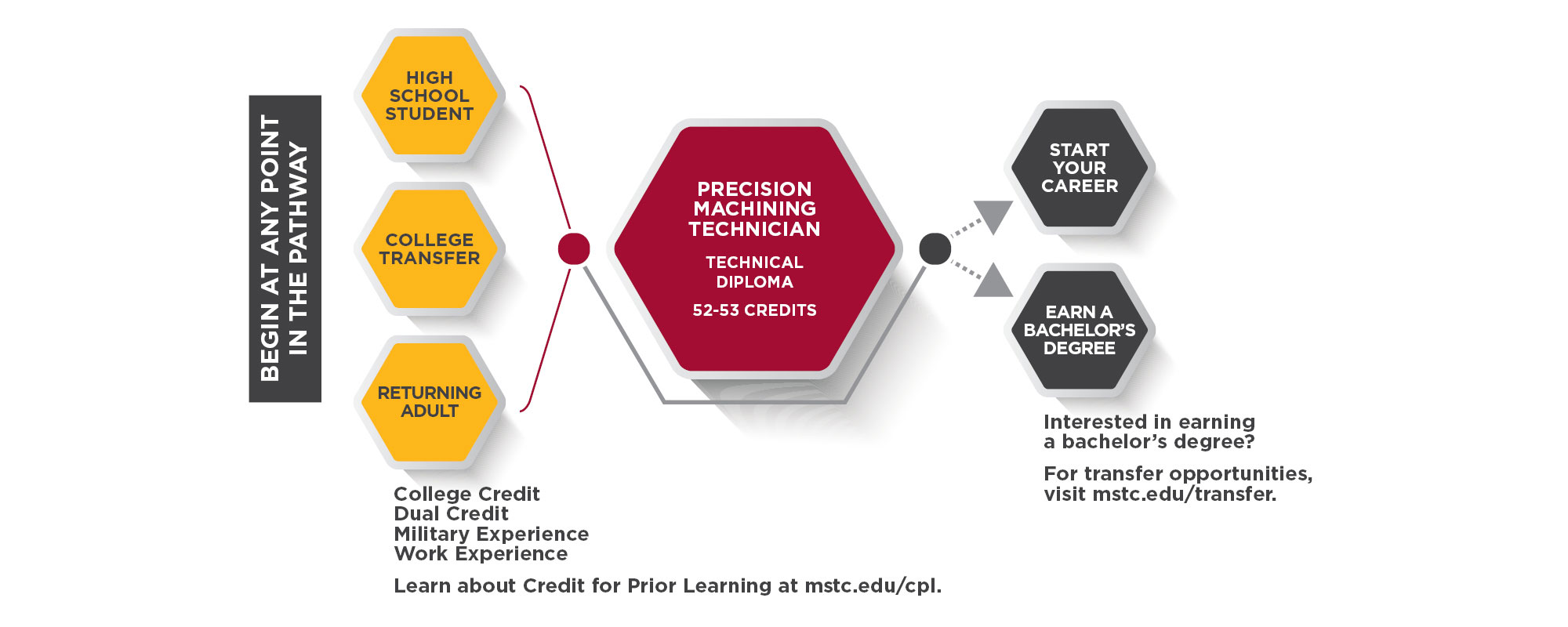

Choose Your Path

Career pathways help you take your education one step at a time to maximize your investment and make college fit your life. Earn a credential and start using it in the workforce. Continue with another stack of related courses to gain a more advanced diploma or degree. Explore this program’s pathway in the graphic below. For an even quicker first step to a degree or diploma, check out our short-term certificates.

Transfer • Dual Credit • Credit for Prior Learning