Industrial Mechanical Technician

Why choose Industrial Mechanical Technician?

- Machines are the lifeblood of manufacturing. Without industrial mechanics, these industries would cease to exist.

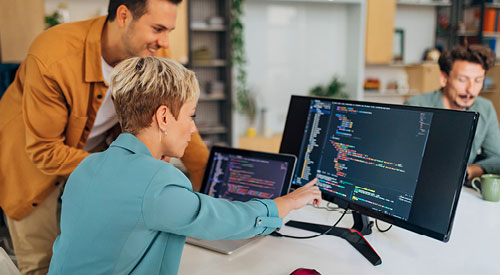

- A great career for those who would like to combine knowledge of mechanical principles, electrical systems, and computer programming in the troubleshooting and repair of sophisticated equipment.

- Provides numerous career opportunities in central Wisconsin with excellent pay and room to advance.

Program Locations

Wisconsin Rapids Campus

500 32nd Street North

Wisconsin Rapids, WI 54494

Delivery:

In Person

Daytime

Full-Time or Part-Time

Varying Class Schedule

Length of Program: Two Years

Credits: 60

Start Dates: Fall or Spring

Start at any time or campus by taking general education courses.

What You'll Learn

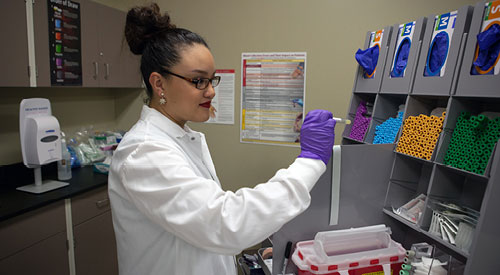

Mid-State’s Industrial Mechanical Technician program will give you the hands-on foundation necessary to confidently maintain, repair, and operate mechanical and electrical machinery and equipment in an industrial environment.

You will learn to align, maintain, repair, and replace machine components as well as gain understanding of predictive and preventive maintenance, reliability-centered maintenance, automation, and many other topics. The program emphasizes safety in the workplace and includes many hands-on and interactive classroom experiences and lab/shop activities.

Outcomes

- Demonstrate safe work procedures.

- Install industrial equipment and systems.

- Maintain industrial equipment and systems.

- Troubleshoot industrial equipment and systems.

- Repair industrial equipment and systems.

- Communicate technical information.

Technical Standards

Students in this program should be able to meet its specific technical standards. These are the essential skills and abilities needed to be successful in the program, with or without reasonable accommodation. It is important to review and understand these standards before applying to the program.

View Technical Standards For This Program

Employability Skills

- Behave Responsibly: Ethical Behavior, Self-Responsibility, Conflict Resolution, Collaboration

- Communicate Effectively: Writing, Technical Documentation, Listening, Speaking, Interpersonal Communication, Reading

- Critical & Creative Thinking: Inquiry, Evidence Collection, Analysis, Reasoning, Reflection (Metacognition)

- Cultural, Social, & Global Awareness: Global Awareness, Social & Cultural Awareness, Social Responsibility

- Use Appropriate Technology: Use of Technology, Confidentiality, Security, Digital Civility

Learn more about employability skills at Mid-State.

Estimated Entire Program Cost

Cost based on the 2025/26 academic year.

- Tuition & Fees: $10,816.00

- Books: $1,410.68

- Supplies, Uniforms, and/or Exams: $0

- Total Estimated Cost: $12,226.68

Financial Aid Eligibility

This program is eligible for full Financial Aid.

Cost of Attendance

Learn more about Cost of Attendance, an estimated budget that includes categories of expenses a student can expect to incur while attending.

This course has options available to receive credit for prior learning (CPL) or work experience.

| Catalog# | Title | Credits | |

|---|---|---|---|

| 10605105 | Electrical Circuits I | 3 | |

| 10804107 | College Mathematics | 3 | |

| 10801195 | Written Communication | 3 | |

| -or- | 10801136 | English Composition 1 | 3 |

| 10462110 | Material Handling | 2 | |

| 10462132 | Machine Shop Fundamentals | 3 | |

| 10462102 | Bearings & Lubrication Systems | 2 | |

| Term Total | 16 Credits | ||

| Catalog# | Title | Credits | |

|---|---|---|---|

| 10462133 | Electric Controls for Industrial Automation | 3 | |

| 10801196 | Oral/Interpersonal Communication | 3 | |

| -or- | 10801198 | Speech | 3 |

| 10462107 | Industrial Safety | 2 | |

| 10623106 | Introduction to AutoCAD | 1 | |

| 10623114 | Intro to Inventor | 1 | |

| 10462122 | Preventive, Predictive, and RCM | 2 | |

| 10809103 | Think Critically and Creatively | 3 | |

| Term Total | 15 Credits | ||

| Catalog# | Title | Credits | |

|---|---|---|---|

| 10462104 | Fluid Process Systems | 3 | |

| 10605117 | Automation 1 - Beginning PLC | 3 | |

| 10462106 | Mechanical Power Transmission | 3 | |

| 10809198 | Introduction to Psychology | 3 | |

| -or- | 10809188 | Developmental Psychology | 3 |

| 10462131 | Industrial Electric Power Applications | 2 | |

| 10442117 | Welding Fundamentals 1 | 1 | |

| 10442118 | Welding Fundamentals 2 | 1 | |

| Term Total | 16 Credits | ||

| Catalog# | Title | Credits | |

|---|---|---|---|

| 10809166 | Introduction to Ethics: Theory and Application | 3 | |

| 10457119 | Fabrication Fundamentals 1 | 1 | |

| 10462120 | Industrial Hydraulics & Pneumatics | 3 | |

| 10605118 | Automation 2 - Advanced PLC | 3 | |

| 10457120 | Fabrication Fundamentals 2 | 1 | |

| 10462134 | Industrial Mechanical Capstone | 2 | |

| Term Total | 13 Credits | ||

| Program Total | 60 Credits |

Instructors

MICHAEL SCHULTZ, BS, MS

Michael earned his master of science degree from Eastern Kentucky University and is an authorized general industry trainer for OSHA 10 and 30. He has 18 years of industry experience and continually advances his own education. He also visits and connects with employers in manufacturing to maintain relationships and make connections between the experiences of his students and the needs of employers.

“Teaching in a technical college is a two-way street. I share my experiences with my students, and each student brings insight and experience as well. This cooperative dynamic enriches the learning for all of us.”

Careers

- Industrial Machinery Mechanic

- Maintenance Technician

- Predictive Maintenance (PM) Technician

- Apprenticeship

- Automation/Robotic Technician

- Field Service Technician

- Industrial Maintenance Technician

- Maintenance Helper

- Maintenance Mechanic

- Oiler

- Packaging Maintenance Mechanic

- Predictive/Preventive Maintenance Technician

- Quality Control Technician

Video

Fast-Track

High school students are eligible to enroll in this program and all courses required. Learn more about Mid-State Fast-Track.

Take the Next Step

“The Industrial Mechanical Technician program was a great experience that created many opportunities for me. Employers are seeking qualified individuals to work in their maintenance departments, and Mid-State’s hands-on training gave me the knowledge and skills needed to start my career in this field.”

FORREST GROSS

MID-STATE ‘14

RUDOLPH, WI

Choose Your Path

Career pathways help you take your education one step at a time to maximize your investment and make college fit your life. Earn a credential and start using it in the workforce. Continue with another stack of related courses to gain a more advanced diploma or degree. Explore this program’s pathway in the graphic below. For an even quicker first step to a degree or diploma, check out our short-term certificates.

Transfer • Dual Credit • Credit for Prior Learning